J&S Machine carries a full line of YLM CNC bending machines capable of covering the many needs of the bending industry. Industries served are: automotive, furniture, appliance, exercise equipment, machine frames, carts, architecture, aircraft, HVAC, and job shop products. The YLM product line has a wide variety of machines and configurations to choose from allowing us to provide a machine that fits both your bending requirements and budget. Starting with the smallest member of the line is a CNC 08 – 5/16” capacity machine. The largest of product line is the CNC 150 – 6” stainless steel bending machine. In between you will find 12 models with a variety of configurations to place the CNC machine offerings at over 50 models.

The YLM CNC product line has a reputation for long lasting machine life, heavy construction, high volume production, and part to part reliability and repeatability. All machines are backed up with a 1 year warranty with extended warranties available. J&S Machine is the US service center and machine stocking location for YLM. J&S Machine is committed to the customers we serve with rapid responses, usually the same day. Applications submitted are thoroughly evaluated by J&S and/or YLM personnel to ensure the responses provided are accurate to make for a successful result. All machines include on site training, electronic and hard copy manuals, and detailed electrical / assembly drawings.

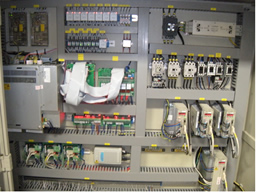

The YLM benders are offered with many features and off the shelf components that are necessary for a complete package to meet your current needs and future growth requirements. The machines are assembled in Taiwan with world class components where world wide support from distributors provides additional resources to the 24/7 support J&S Machine and YLM provides. Some of the brands utilize are: Yaskawa servo motors and drives, Rexroth drive on selected models, Beckhoff I/O system on selected models, Rexroth hydraulics, Omron switches, Rexroth Bosch or HIWIN slide assemblies, and ZF gear reducers powered by a Windows embedded software based control.

Standard machine design features on CNC benders include:

- Air conditioned electrical enclosure to maintain temperature and prolong system components

- Electrical power filtering to stabilize incoming power supplies for an efficient consistent operation

- Control electrical cabinet isolation to minimize vibration transfer to electronics

- Oil filtering system with condition indicator to protect oil supply

- Radiator type oil cooler standard on most models, available on others to maintain oil temperature

- Vibration control machine mounting pads to reduce machine movement during operation

- Spacious well labeled / layout of electrical system for ease of maintenance and efficient operation

- Remote control console for placement in operational location based on application to reduce operator interface time to increase production

- Foot pedal cycle start operation for quick safe loading increasing production

- Safety mat and safety plates with multiple emergency stop placement for operational safety

- Integrated gearbox reducer with multi layer drive chain assembly for smooth controlled operational start / stop movement of bend arm extending the chain life many years beyond traditional hydraulic benders.

- Low profile bend head design uniquely offset from center of machine frame providing clearance for complicated parts that can not be obtained on other brands of equipment.

- Full capacity feed through collet for working with long material that requires additional length beyond the front collet stop system reducing the need for extended models in most applications.

- Low decibel level production noise to reduce operator fatigue and general improvement of shop conditions

- Low working heights for ease of operation increasing production and improved safety of material handling

- Multiple axis operation reducing cycle time and interference for optimum production

|

|

| Hydraulic Tank Layout |

Electrical Panel Design |

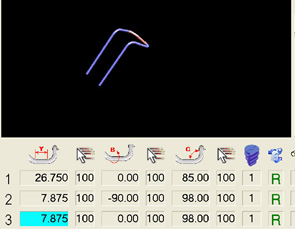

Standard CNC Motion Software package highlighting these functions:

- Developed and supported in-house by YLM software team ensuring quick response to customer needs, longevity in support system, and specifically designed to meet the requirements of the YLM benders

- Unlimited program storage and bending steps for ease of program retrieval on the machine without interfacing to external storage system with one touch USB storage ports for program backup if desired

- Instant diagnostics of program development and machine functions for error free operation

- 3D work piece preview – generated as program is entered above data for viewing to reduce programming errors and increase speed for program development

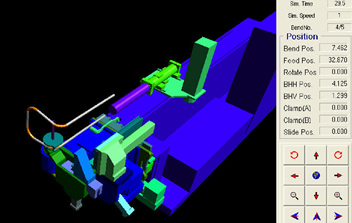

- 3D animation bending simulation with interference identification of movement locations reducing first part production delays and quick feasibility verification

- Batch work function for production with multiple programs automatically increasing production efficiency

- Reverse program function, automatic step feed calculation, tube recapture function, and variable sequence operation program for working quickly and easily with a variety of common difficulties encountered in tube bending operations and applications.

- Automatic cut length calculations streamlining other aspects of the production cycle

- Independent programmable speeds on servo axis for optimum machine usage

- Network ready configuration for integrating to your company system

|

|

| 3D Work Piece Display during Programming |

3D Simulation of Bending |

Standard machine operational features included at no additional cost:

- Mandrel extractor with programmable anticipated early retraction for working with mandrels,

- Multiple sizes of mandrel rods included for future projects

- Automatic mandrel lubrication system utilizes programmable oil flow and air mist for maximizing coolant usage while increasing production capabilities

- Carriage and follower boost on most models for working with thin wall and high strength materials to a tight radius

- Independent level specific adjustable wiper die assembly for adjusting rake and position of wiper die when working with multi radius stacked tooling for ease of setup and optimum tooling placement extending tooling life

- Count down programmable piece counter for controlling production quantities

- On 5A and above models – programmable bending head alignment to carriage for working with compound tooling, specialty tooling designs or adapting tooling from other models with the usage of adapter plates simplifying tooling design or reducing cost of purchasing additional tooling.

- Selectable material holding or auto release of finished part for safe efficient handling

Optional features available on selected models:

- Safety package which includes scanner, interlock safety relays, phase fault detection, machine enclosure guarding, collet closure mat, and hand activated cycle start system.

- Dimple style hole punching for combining operations

- Split die operation for unique shaped material

- Internal collet for short end length operation

- Internal pusher booster system for shorter end part operation requiring boost bending

- Robot ready I/O configuration for robot connection

- Auto loader with seam detection devices for side or over mandrel loading

- Measuring system integration for reverse engineering or automatic part correction

|

|

| Safety Package on CNC 90 |

Hole Punching Option |

|

| CNC38 with Loader with Seam Detection |

|